The clinching process is a method of assembling sheet metal without welding or fasteners.

Clinching process in sheet metal.

It uses the solid die cavity patented by tox pressotechnik.

Steel and stainless steel aluminium and or non ferrous materials.

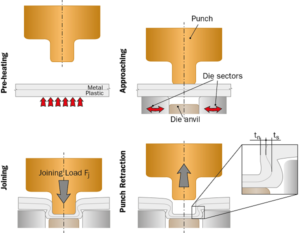

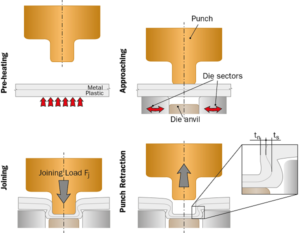

The process is generally performed at room temperature but in some special cases the sheets can be pre heated to improve the material ductility and thereby avoid the formation of cracks during the process.

The clinching technique is an innovative process for the mechanical cold junction of sheet metal.

It is suitable for ductile metal sheets from around 0 5 to 3mm thick up to a total joint thickness of about 6mm.

Clinching or press joining is a bulk sheet metal forming process aimed at joining thin metal sheet without additional components using special tools to plastically form an interlock between two or more sheets.

With this joining technique metal parts are deformed locally without the use of any consumables.

While the sheet metal may be preheated the process is typically performed at room temperature.

Multiple materials with different individual thicknesses can be assembled at the same time based on this cost effective fast and clean process.

Rivclinch is a cost effective environmentally friendly.

With the clinching process sheet metals of different thicknesses or other materials even with adhesives or other intermediate layers are joined in a cold forming process.

The tox clinch procedure is a proven substitute for welding screwing riveting.

To perform clinching a metalworking company secures and aligns the sheet metal between the punch and die.

Find the right clinching joint for your sheet metal joining application.

Clinching is characterized by a series of advantages over competitive technologies.

Clinching also known as press joining is a high speed mechanical fastening technique for point joining of sheet metal components.

Tox clinching is a simple joining technique that does not require heat or additional elements the clinching process produces a button type positive connection of two or three layers of sheet metal using a cold forming process.

In industrial applications clinching is being applied for single sheet thicknesses of 0 1 mm up to a total layer thickness of 12 mm 47 and up to 800 n mm 2 5 7 lbf in2.

Once in place the punch is engaged thereby pressing down on the sheet metal with low to medium force.